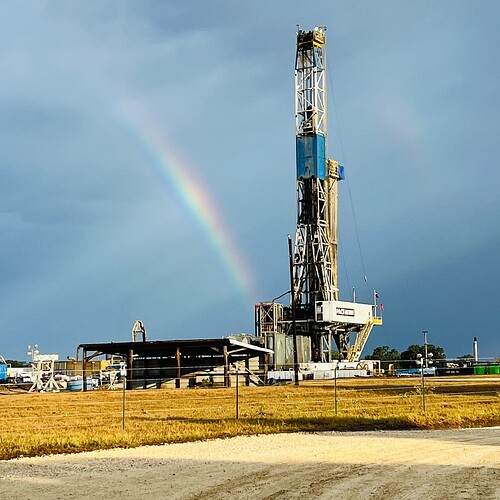

Pecan pad was just burning diesel fuel. They had Halliburton wire line unit taking ore samples that were send off to geologist. Hot shot truck brought in directional tools not sure what that means off course are what. Guess rig crew had 4 easy days.

Monster rock pipeline should be doing Hydro testing Saturday or Sunday depends on the weather

Halliburton unit there running open hole logs and taking sidewall cores (probably rotary) in vertical hole. Samples being analyzed for various reservoir properties (porosity, perm, organics, thermal maturity, etc.).

Directional tools on site to start drilling the curve for the lateral - expensive equipment / so no reason to have them on location until they were needed.

Guess the directional tools did their job on the lateral. Got pipe trucks coming last night and this morning also they brought their own forklift..

I assume that you mean that they have started delivering production casing to set in the lateral once the drilling has been completed.

Yes casing for the lateral 13 loads. Forklift driver said well at San Diego Tx had 17 loads. At the rate they drilling shouldn’t be much longer at what Iam seeing.

Getting the production casing on location early allows for inspection and detailed measurements of each casing joint.

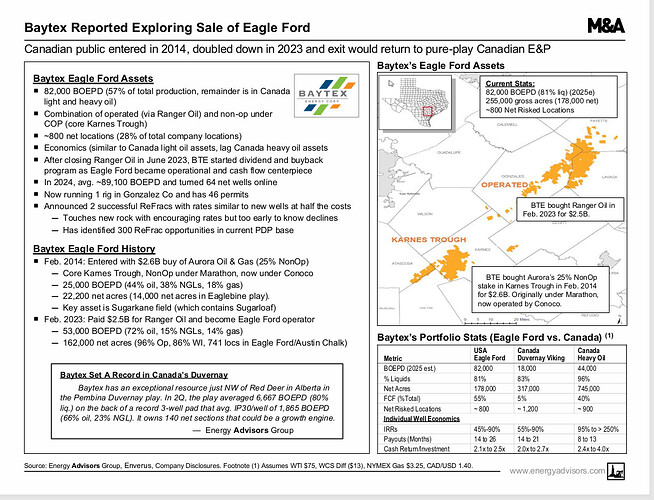

As to the rumored Baytex divestment in the EF / AC trend, please see info below

BayTex.pdf (514.7 KB)

Is this casing for the Monster lateral or the Reimers lateral?

I would venture that this casing is for the Monster lateral since that is first well being drilled from this pad.

But I would not be surprised if the casing for the soon to be drilled (ideally) Reimers lateral is also being delivered and stacked on location at this time.

Casing lengths vary (40’-46’ each joint), but assuming 40’ casing joints, two 10,000’ laterals would require 500 joints of production casing. And this does not include the casing that is needed to cover the curve of the lateral as well as that part of the vertical wellbore that needs to be protected / cased cemented.

50-60 joints per flatbed truck load, so at least two truckloads of casing for the two laterals

Monster rock, maybe they hit the jackpot finally pulling all the pipe after four days of straight drilling.

Nice photo of rig and operation.

Possible that they are at TD in the lateral after four days of continuous drilling. Assuming 10,000’ lateral, that would only be about 100’ per hour drilling rate / highly possible in today’s Hz drilling world.

As to “jackpot” - #1 objective for any Hz operator is to keep the lateral in the target zone for the entire length of the lateral. Then the priority shifts to getting casing to TD with a good cement job over the entire length.

Only then can they think about exploiting the jackpot with an efficient frac job (with anywhere from 50 to 70 separate frac stages).

Lots of room to screw things up and get a less-than-ideal completion.

Do the frack tanks used during flowback only contain water ? or do they also have oil that can be transferred to a tanker truck ?

Spoke with a new guy for an hour today about the Pecan farm units. He thought they are working on the Reimers unit now…..from the conversations it seems like everyone is referring the the monster rock unit. Anyone have any info on it…was told earlier rig is suppose to be leaving in a couple of weeks from that pad.

Also spoke with someone who owns companies that buys mineral interest. He would not give the sellers name, but stated that he is buying someones interest now that is in a Redhawk unit…that the mineral owner told him the results are not promising. (So why does he still want to buy it?)

Modern energy had to change ‘Nelda Sue” unit name back to “Grover” which it was previously….I did not think they could change the name.

Also “heard” from a reliable source that EOG is considering a Baytex purchase. Baytex has a conference call this Friday that I will be on…so I will see what if anything is mentioned.

Changing well names is more common than you think - just takes paperwork.

EOG is one of the few companies that could do the Baytex purchase and make if work - their expertise in the Eagle Ford / AC trend makes Baytex a logical “bolt on”

Albeit an expensive one. Could be a stock deal (or hybrid cash and stock)

Portable frac tanks are used for both water and oil. Oil storage in frac tanks not as efficient as having oil go to permanent storage tanks, but it works until those are in place.

I caution any comments you get from people on or around the site - false information is easy to transmit and may be done either intentionally or due to lack of expertise as to what is happening.

Even if a well is “not promising” (and way too early to tell - need months of production to see decline profile and EUR projections), mineral are still valuable. Future wells on that same block may be drilled differently / different target zone / different frac approach.

I don’t recall the exact term but mineral rights trump surface rights. So if you own surface and minerals and sell the minerals, you’re basically giving up your right to say ‘no surface operations’ unless you somehow include that in the fine print of the sales document.

Yes, surface is subordinate to the minerals (that may be the term you’re referring to). In Texas, there is no requirement to pay surface damages and you have the right to develop your asset (the minerals) and force your way onto the property. However, that is never the smart way to do it, which is why surface use agreements exist.

Also, as Rock Man noted, I wouldn’t trust a mineral buyer, even if you know him. It isn’t going to do them any good to share what they know because it could bring on competition, so they’re likely to fudge the story so they can buy low.